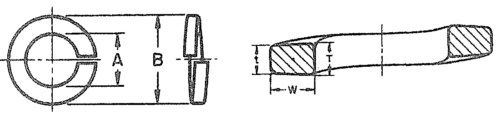

| Nominal Washer Size | A Inside Diameter Min | A Inside Diameter Max | B Outside Diameter Max² | W Washer Section Width Min | T + t / 2 Washer Section Thickness Min |

|---|---|---|---|---|---|

| #2 - 0.086 | 0.088 | 0.094 | 0.172 | 0.035 | 0.02 |

| #3 - 0.099 | 0.101 | 0.107 | 0.195 | 0.04 | 0.025 |

| #4 - 0.112 | 0.115 | 0.121 | 0.209 | 0.04 | 0.025 |

| #5 - 0.125 | 0.128 | 0.134 | 0.236 | 0.047 | 0.031 |

| #6 - 0.138 | 0.141 | 0.148 | 0.25 | 0.047 | 0.031 |

| #8 - 0.164 | 0.168 | 0.175 | 0.293 | 0.055 | 0.04 |

| #10 - 0.190 | 0.194 | 0.202 | 0.334 | 0.062 | 0.047 |

| #12 - 0.216 | 0.221 | 0.229 | 0.377 | 0.07 | 0.056 |

| 0.25 | 0.255 | 0.263 | 0.489 | 0.109 | 0.062 |

| 0.312 | 0.318 | 0.328 | 0.586 | 0.125 | 0.078 |

| 0.375 | 0.382 | 0.393 | 0.683 | 0.141 | 0.094 |

| 0.438 | 0.446 | 0.459 | 0.779 | 0.156 | 0.109 |

| 0.5 | 0.509 | 0.523 | 0.873 | 0.171 | 0.125 |

| 0.562 | 0.572 | 0.587 | 0.971 | 0.188 | 0.141 |

| 0.625 | 0.636 | 0.653 | 1.079 | 0.203 | 0.156 |

| 0.688 | 0.7 | 0.718 | 1.176 | 0.219 | 0.172 |

| 0.75 | 0.763 | 0.783 | 1.271 | 0.234 | 0.188 |

| 0.812 | 0.826 | 0.847 | 1.367 | 0.25 | 0.203 |

| 0.875 | 0.89 | 0.912 | 1.464 | 0.266 | 0.219 |

| 0.938 | 0.954 | 0.978 | 1.56 | 0.281 | 0.234 |

| 1 | 1.017 | 1.042 | 1.661 | 0.297 | 0.25 |

| 1.062 | 1.08 | 1.107 | 1.756 | 0.312 | 0.266 |

| 1.125 | 1.144 | 1.172 | 1.853 | 0.328 | 0.281 |

| 1.188 | 1.208 | 1.237 | 1.95 | 0.344 | 0.297 |

| 1.25 | 1.271 | 1.302 | 2.045 | 0.359 | 0.312 |

| 1.312 | 1.334 | 1.366 | 2.141 | 0.375 | 0.328 |

| 1.375 | 1.398 | 1.432 | 2.239 | 0.391 | 0.344 |

| 1.438 | 1.462 | 1.497 | 2.334 | 0.406 | 0.359 |

| 1.5 | 1.525 | 1.561 | 2.43 | 0.422 | 0.375 |

Helical Spring Lock Washers (Split Lockwashers)

Regular (Medium)

Standard size range: #2 Diameter (.086) to 1-1/2″ Diameter

Styles:

- Light

- Regular (Medium)

- Heavy

- Extra Duty (Extra Heavy)

- Hi-Collar {For Socket Cap Screws)

Materials & Finishes:

- Carbon Steel, Heat Treated

- Plain

- Stainless Steel

- Bronze

- Monel

- Zinc Plated

- CAD Plated (Type I & II)

- Hot Dip Galvanized

- Many Other Materials and Finishes Available

The regular (or medium) style is by far the most popular. Our stock on this style is extensive. We also stock all the other styles in many of the standard sizes and finishes. Our shelf stock contains sizes up to 3″ in diameter – of course not every size is available in every style and material. Check with us for specs, prices & availability.

Tooth Lock Washers

This style is recommended for applications where the teeth must be hidden under the screw head. Internal type lockwashers provide maximum locking efficiency where finished appearance is a factor.

This style offers the greatest locking efficiency and should be used wherever possible. Optimum locking action is assured since teeth maintain largest area of contact with nut or screw and work piece.

These washers are for use where a larger bearing surface is desired, for oversize or elongated screw holes. Extra teeth make it ideal for electrical grounding purposes.

Countersunk type lockwashers are for use with flat or oval head screws in either 82° or 100° countersunk angles. Some sizes are available with internal teeth.

Standard sizes range from #2 screw diameter to 1-5/ 16″ bolt diameter.

Internal: #2 to 1-5/16″ — External: #3 to 1″ — Internal-External: #6 to 5/8″ — Countersunk: #2 to 1/2″

Steel, Stainless, and bronze are available in many sizes.

Call or contact us for prices & specifications.