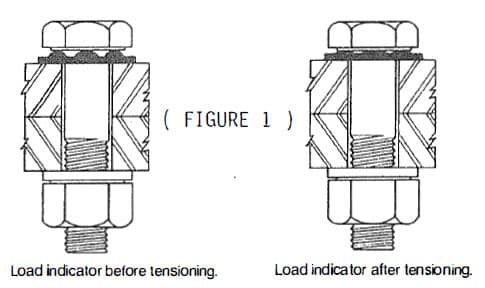

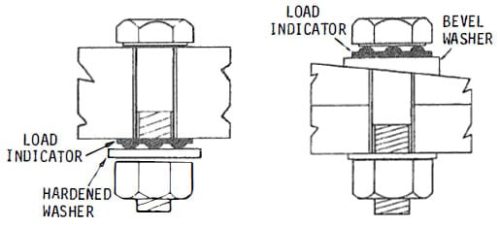

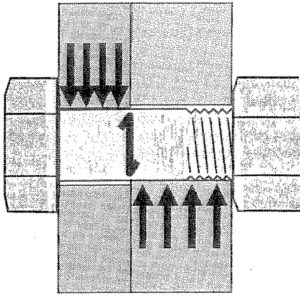

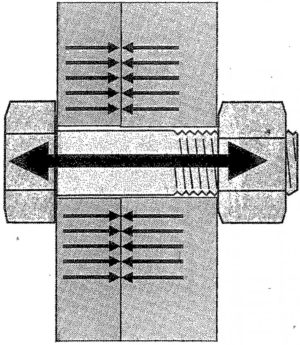

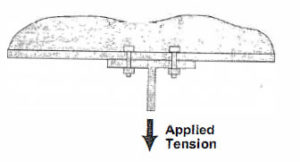

The Load Indicator Washer is a hardened round washer which has a group of protrusions pressed out of the flat surface. In use, the Load Indicator is placed on a bolt with the protrusions bearing against the hardened surface of the bolt-nut-washer assembly, usually the underside of the bolt head. As the bolt is tightened, the bolt clamping force causes the protrusions to partially flatten, closing the gap between the Load Indicator Washer and the bolt head as shown in Figure 1. When the gap is reduced to a prescribed measurement, the bolt has been properly tightened.

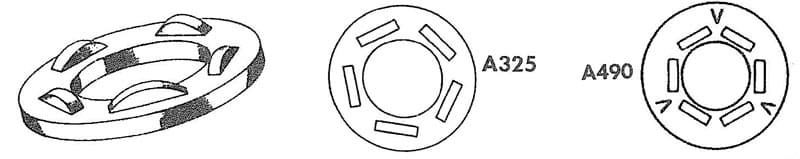

Load Indicator Washers are produced tor both A325 and A490 high-strength structural bolts, and are identified appropriately to avoid any possibility of mixing the two different strength levels.

Load capacity of the Load Indicator Washer is varied for each bolt diameter and grade by changing the number and size of the protrusions.