There are many different kinds of locknuts. Pictured below are some of the well known types and styles. Most of the popular sizes — Metals — Materials & finishes are usually available in one or more of the kinds depicted. Call or contact us for more information.

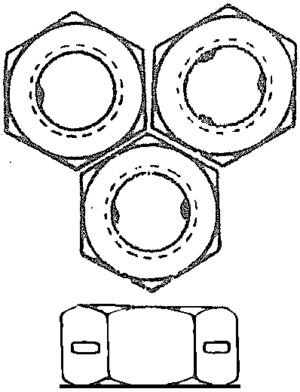

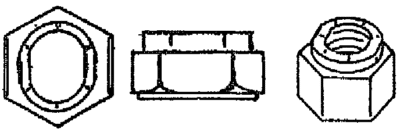

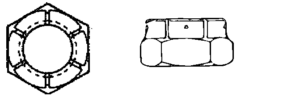

Prevailing-Torque Types

Trade Names:

Two-Way

Reversible

Centerlock

For Use With Grade 2 Bolts

Usually Supplied Plated

For Simple, Inexpensive

Locknut Applications

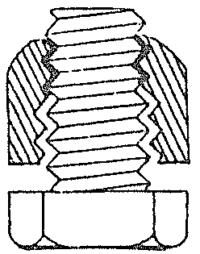

Cross Section View

(Drawn Over Scale)

To Show Thread Engagement

1,2 or 3 round, rectangular or other shaped indentations compressed onto the flat sides of the nut distorts the internal threads causing a controlled locking action when engaged with external mating threads.

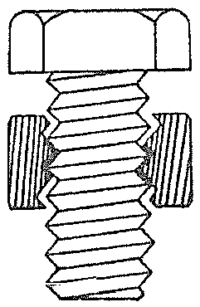

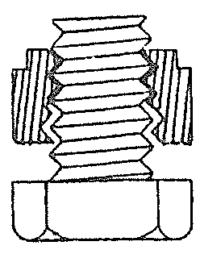

The locknuts pictured below are all similar. Their locking features and general shape are approximately the same. During the manufacturing process the internal threads are deformed by applying pressure on the outside of the nut. The deformed threads produce a friction fit with the external threads of the bolt. This friction fit is well controlled and induces a locking action that allows for temperature and vibration variations.

Trade Names:

Stover

Conelock

Uni-Torque

Crown Lock

& Others

Elliptical threads (the locking feature) are formed in the manufacturing process by applying pressure to the sides of the nut near the top.

This nut is indented directly on the top surface to deform the threads. This locking feature works on the same principle as the one above, giving the same results.

Compression to the sides and the collar area form the the elliptical threads that assures the locking fit.

The most popular material for the above nuts is grade “8” or “C” and serves grade 2, 5 and 8 bolts.

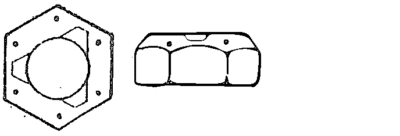

Many manufacturers produce the same locking nut in a “flange” type configuration. Check with us for prices and availability.

Available in all popular sizes. Full, heavy & jam patterns clinch & swage nuts. N.C & N.F threads. Steel (plain & plated) corrosion resistant steel. A very good nut for all applications.

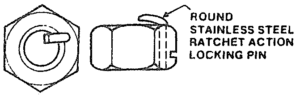

Positive locking action under shock or vibration. The pin acts as a ratchet during assembly, preventing any tendency to back-off under vibration. Reusable.Steel, 2H, A325, hot dip galvanized. Contact us for specs.

The nut spins freely on the bolt until the threads enter the nylon collar, where they impress but do not cut threads into the nylon. This compression forces metal-to-metal contact between internal and external threads, causing a friction fit that meets existing vibration-proof standards. All popular metals and sizes. High temp & reduced sizes O.K.

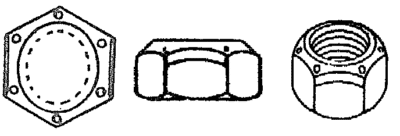

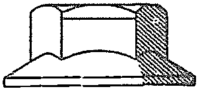

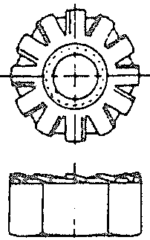

Bearing Types

Nuts are pre-assembled with tooth-type lockwashers to form free-spinning locknuts. Unlike prevailing torque type nuts, this type of bearing locknut does not lock onto mating threads in any manner. It must be firmly clamped against a bearing surface so that the teeth of the lockwasher may “dig in” and perform their vibration resistant duties. This type of nut can also be assembled with helical-spring and conical-spring lockwashers. The tooth-type is by far the most popular and is usually supplied zinc plated. Their range is from #4 diameter to 3/8″ diameter.

Trade Names:

“Keps” — “K-Lock” — “Tites” and Others.

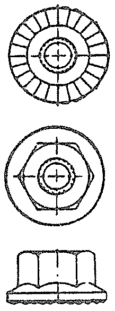

The bearing (underside) surface of this nut has a series of encircling serrations or teeth. These teeth are designed so that they do not grip or impede rotation as the nut is assembled onto the bolt. When the nut is fully wrenched down the teeth resist “back-off” as vibrations or other loosening forces are applied. These nuts are reusable.

This type of nut is also made without the flange configuration.

One-piece, all-metal, free spinning.

Trade Names:

“Whiz-Lock” — “Flange-Lock” — “Tensilock” and Others.

There are many more styles, kinds and trade names on the market.

We can quote price and availability on any of them, but we do not attempt to name all of them here.

Call or contact us for prices & specifications.