The A325 F1852 & A490 F2280 controlled-tension “breakoff” bolt is designed to shear off the grooved spline and complete tightening to a prescribed minimum tension. This insures that the bolt tension achieved is by the “turn-of-nut” method of conventional a325 hex bolts, nuts, and washers. It fully meets the requirements of the engineering foundation’s research council on riveted & bolted structural joints.

Mechanical Properties

| Specification | Nominal Size (Diameter) | Proof Load (PSI) | Yield Strength Min (PSI) | Tensile Strength Min (PSI) |

|

|---|---|---|---|---|---|

| Bolt | A325 Carbon Steel Quenched & Tempered | 0.63" Through 1" | 85000 | 92000 | 120000 |

| Nut | A563 Grade DH Carbon Steel Quenched & Tempered | 0.63" Through 1" | 144000 | --- | --- |

| Washer | F436 Hardened Steel Flat Washer | 0.63" Through 1" | --- | --- | --- |

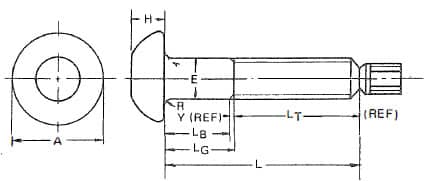

Dimensions & Shape

| Nominal Size or Basic Bolt Diameter | Body Diameter (E) | Head Diameter (A) | Head Height (H) | Radius of Fillet (R) | Thread Length (LT - Ref) | Transition Thread Length (Y - Ref) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Basic | Max | Min | Basic | Max | Min | Max | Min | Basic | Max | |

| 0.63 | 0.642 | 0.605 | 1.181 | 1.26 | 1.102 | 0.39 | 0.403 | 0.378 | 0.062 | 0.021 | 1.25 | 0.22 |

| 0.75 | 0.768 | 0.729 | 1.457 | 1.535 | 1.378 | 0.47 | 0.483 | 0.455 | 0.062 | 0.021 | 1.38 | 0.25 |

| 0.88 | 0.895 | 0.852 | 1.614 | 1.713 | 1.516 | 0.55 | 0.563 | 0.532 | 0.062 | 0.031 | 1.5 | 0.28 |

| 1 | 1.022 | 0.976 | 1.811 | 1.91 | 1.713 | 0.61 | 0.627 | 0.591 | 0.093 | 0.062 | 1.75 | 0.31 |

Strength Properties And Hardness

Dimensions & Shape Of Nuts

Dimensions & Shape Of Washers

Available On Request

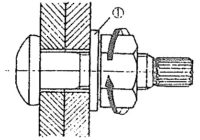

Installation Procedure

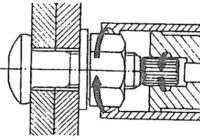

Step 1:

Place the bolt into the connection with the washer (1) under the nut.

Finger tighten the nut.

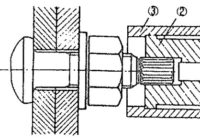

Step 2:

Fit inner socket (2) over the grooved spline and push the wrench slightly and then engage the outer socket (3) over the nut.

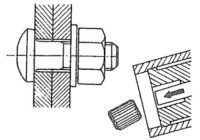

Step 3:

Turn the wrench on. The outer socket rotates and the bolt will be tightened until the required bolt tension is reached.

Step 4:

Remove the outer socket from the nut and depress the ejecting lever to discharge the sheared extension from the inner socket of the wrench.

For More Information

Price & Delivery

Contact Us!